At Saint Clair Systems, we build technology that controls temperature and viscosity - creating huge savings in time and material caused by “uncontrollable” variations. Learn how we can support your process.

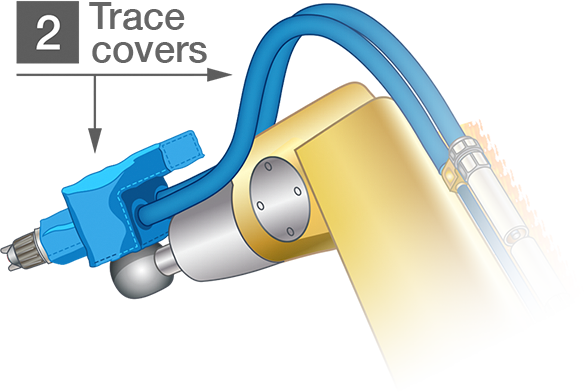

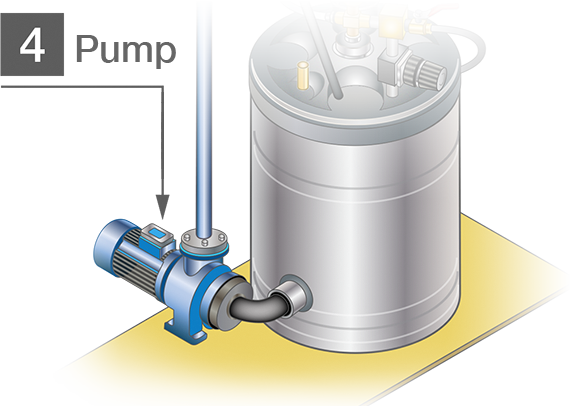

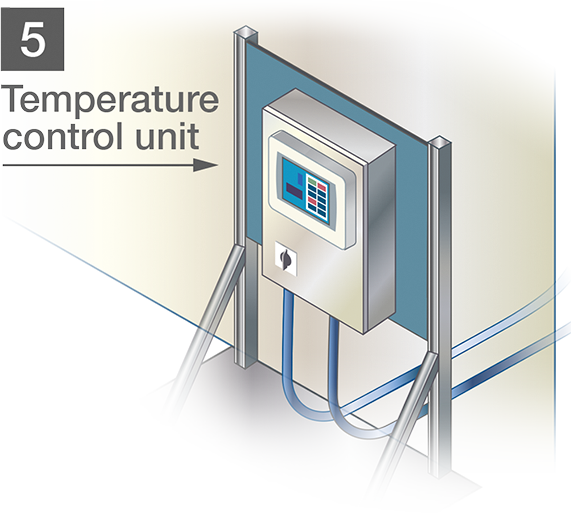

FREE PROCESS EVALUATIONAs material moves from its origination point to the point Of dispense, temperature can change. Slight variations can have a dramatic impact on material cost. Here's how we keep temperature and viscosity consistent as material moves through a process.

.png)

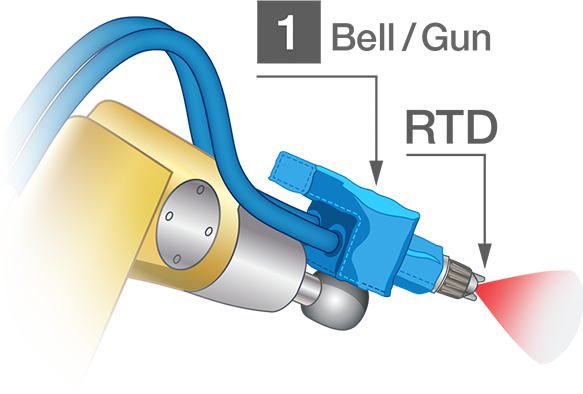

The RTD senses temperature in the material path as close to the Point of Dispense as practical, ensuring that it’s always accurate.

Temperature affects viscosity, and viscosity affects film thickness in your coating process. With adequate temperature control, you’ll save money on solvents and coatings while delivering consistent results.

Learn more

Bonding defects can almost always be traced to variations in temperature and viscosity of the bonding agent and primer system. SCS addresses these directly at the point-of-application to assure consistent, predictable and repeatable outcomes.

Learn more

Whether you are painting small parts or large truck bodies, even the slightest change in temperature or viscosity can lead to inconsistent coverage, quality control problems, excess material usage, or other issues that will impact your final product.

Learn more

Improper viscosity drives up costs while making quality worse. Our free guide shares the impact of temperature on improper viscosity and, more importantly, how to fix it.

While Temperature Control Systems are essential, they aren't something you purchase every day. Here's how we help you get the right system for your process.

If you think there may even be a chance that temperature fluctuations are affecting your process, get some free advice from one of our experts.

Learn moreWe tour your process using comprehensive checklists, a thermal imaging camera, and a great deal of experience, and generate a report focused on your unique concerns.

Learn moreBy installing two inline viscosity sensors, we can help quantify how much your viscosity changes during your dispensing process and whether it's worth doing something about.

Learn moreEither it works for your process or it doesn't. Our team will install a system in your plant and with actual field performance you get to decide with Your Process, Your Data and Your Results.

Learn moreIf you’re tired of unpredictable results, high material costs, and unnecessary defects, we’d love to talk.

Get in Touch