Analyze your finished spray within minutes - before you start production.

With SprayVision via Exclusive North American Distributor, Saint Clair Systems, you can say goodbye to expensive production overruns, low First Pass Yields, and waiting for paint to dry. This technology helps you:

Reduce setup time by 25% while increasing First Pass Yield.

Know how things will look before you start production.

Get actionable measurements without waiting for paint to dry.

Reduce VOC emissions during the production process.

Liquid Coating Magazine, February 2021

A collaboration between CFAN, SprayVision, & Saint Clair Systems used an innovative film measurement system to investigate ways to improve first-time yield. Learn how it works & how it might help you improve your own first time yields.

White Paper, January 2021

This paper examines how CFAN, a supplier of jet engine turbine blades to GE Aerospace, employed the SprayVision system, to investigate the unique traits of their automated blade painting system with the goal of refining their First Time Yield (FTY) percentage from <90% to >95%.

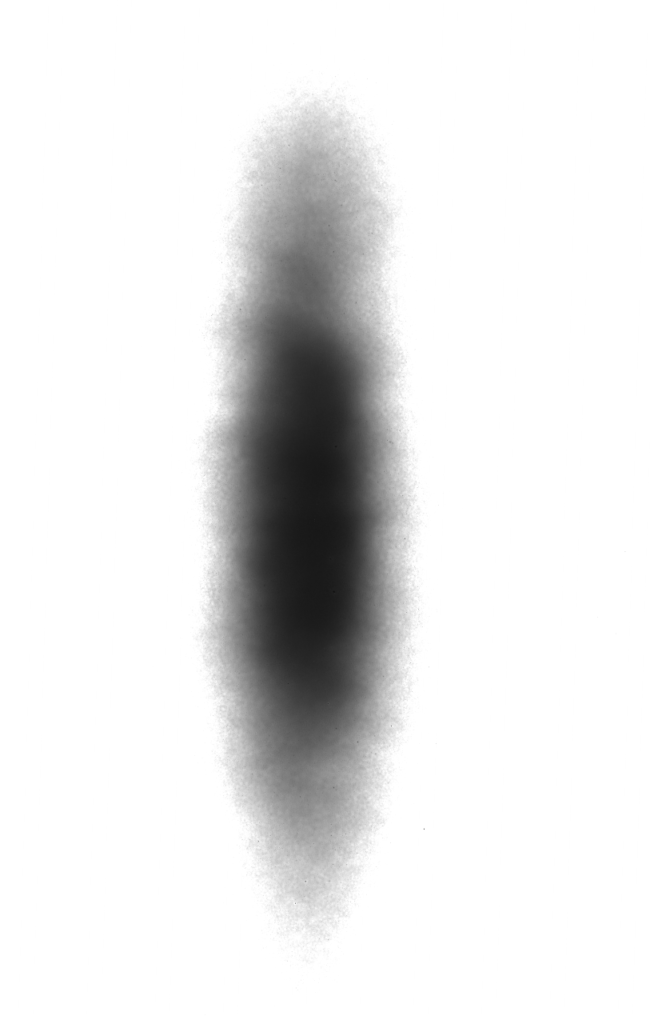

Capture the actual spray pattern before applying paint to the part. Compare it to the production standard without sacrificing the production part.

Capture the pattern and measure it to standard without waiting for the paint to dry. Determine whether you're ready for production while the paint is still wet.

.png)

If the pattern is ok, move forward with production and increase your First Pass Yield.

Yes, some paint will end up on the glass. When the paint is wet, a simple alcohol wipe is usually sufficient. That being said, because the SprayCapture Unit is designed for industrial use, the scanning bed is made of real glass, not a polymer, so it is resistant to all solvents used in painting operations when more aggressive cleaning is required.

The SprayCapture Unit is designed for industrial use, so the scanning bed is made of real glass, not a polymer, and it is well-sealed so it is resistant to all solvents used in modern painting operations.

Yes, the foils can be measured both wet and dry.

To maintain measurement accuracy, it is recommended that new foils be used for each capture and that they be thrown away after use.

Yes. There is sufficient space between the flakes for the light to penetrate and provide accurate measurements.

Yes, one software license is required per SprayCapture Unit.

This parameter is only important during the calculation of transfer efficiency, and is entered manually as part of that process.

The A2 SprayCapture Unit can capture both A2 and A3 foils and can therefore be used for both guns or bells whereas the A3 SprayCapture Unit is generally reserved for use with guns.

Ready to say goodbye to expensive cost overruns, slow processes, and poor quality? Let's talk.