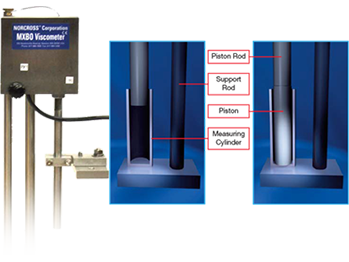

Our engineers have created viscometers and sensors that use the simplest, yet most sensitive and reliable principles of operation. Our inline viscometers and intuitive viscosity software provide excellent ease of use and reliability.

Our viscosity equipment is so reliable that many have been in operation for more than 30 years.

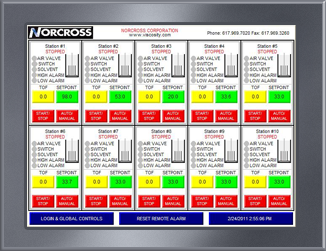

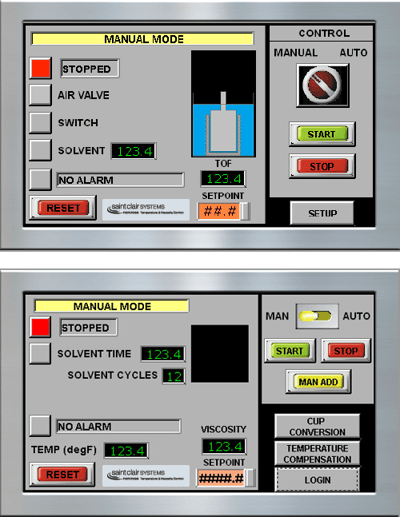

Our MP3000/ 3500 Series Viscosity Controller offers an entirely new standard of versatility and economy in a compact PLC/ Touch Screen package.

We reported increased stability in striation patterns when applying PVC to aluminum to create a woodgrain finish. We reported significant reductions in color match issues as a result of consistent film build

- Alsco

Steelscape reported reduced “ropiness” when applying Polyester to steel resulting in a finish that “looks sprayed rather than rolled, Steelscape reported 75% reduction in solvent pop due to reduced solvent addition. Steelscape reported 100% reduction in solvents added to primers and backers and 60% reduction in solvents added to finish coats. This was the easiest capital project implementations that we’ve ever done!

- Ron Hurst

- Steelscape

Our system provided the biggest bang for the buck of any capital project so far!

- Jay Michae

- Ternium

Reported solvent reductions between 80% - 100%

- Ternium Shreveport

As part of our ongoing continuous improvement plan at Roush, we decided to take a more aggressive approach to our temperature control in the paint shop. The resulting quality improvement was immediately noted and helped drive our FTC (First Time Capability) up and sustain it where we needed it to be.

- Patrick Henterly

Roush Manufacturing

At Valspar, we formulate our paints to run under a variety of different conditions and process variables. One of the primary variables is the paint temperature, which can vary from 40°F to 100°F based on the conditions at the coil coating facility. This wide swing in temperature can play havoc with both paint viscosity and application setup. Having consistent and targeted paint temperature removes this process variable and its effects from the equation. Additionally, having consistent paint temperature ensures optimal (minimal) usage of expensive reducing solvents to attain the desired viscosity and applied paint film thickness.

- Kent Hatch

Valspar Corporation

“Being able to control the temperature within a narrow range as paint is being used can be very beneficial. The most obvious benefit is a reduced amount of solvent usage. This is not only more economical for the coater but also reduces the environmental impact and health risks to their employees. Reducing the amount of solvent added [provides] additional benefit to the performance of the paint being used. The two major benefits are: Reduced possibility of having solvent popping or blistering problems. The addition of too much solvent to certain paints or certain colors of paints may cause color shifts or gloss changes and by reducing the amount that needs to be added this can be avoided.”

- Herald Cales

Akzo-Nobel