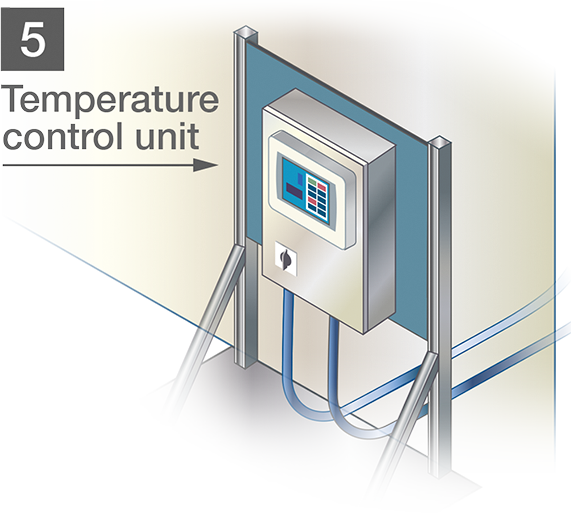

Temperature Control

Most systems fail to maintain temperature at the point of dispense. The result? Uneven application, rework, and wasted time and materials. Our unique technology keeps temperature consistent and costs down.

FREE PROCESS EVALUATIONMost systems fail to maintain temperature at the point of dispense. The result? Uneven application, rework, and wasted time and materials. Our unique technology keeps temperature consistent and costs down.

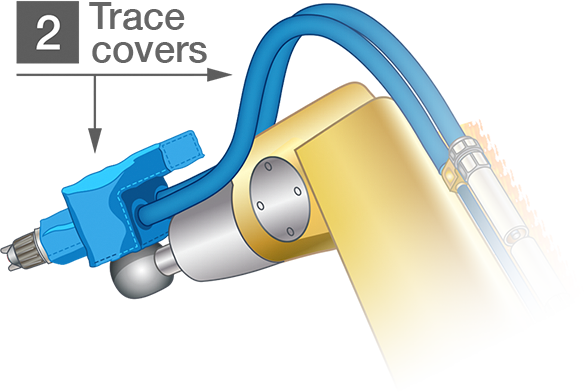

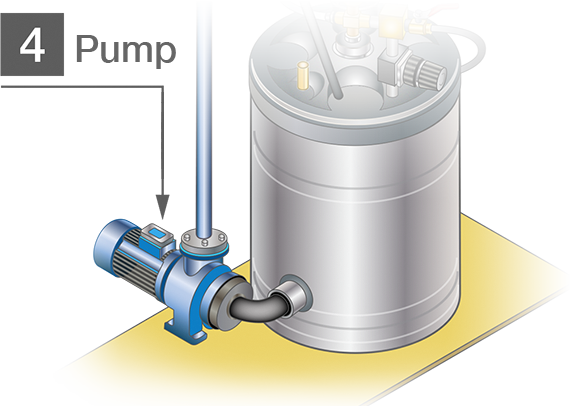

FREE PROCESS EVALUATIONThere are several points in a process where temperature control happens. Swipe left or right to see how Saint Clair Systems technology can help you to keep your temperature controlled and consistent from the TCU to the Point of Dispense.

.png)

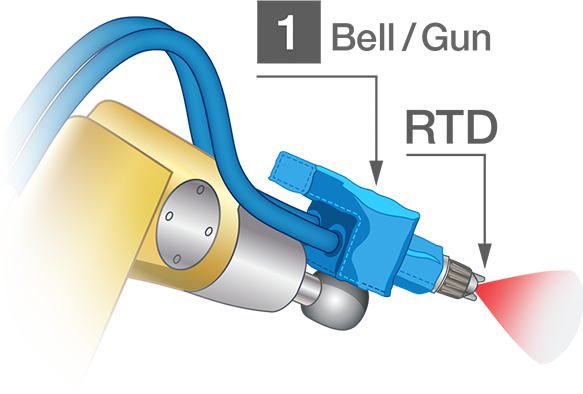

The RTD senses temperature in the material path as close to the Point of Dispense as practical, ensuring that it’s always accurate.

If you’re like many companies supplying painted parts for an industry where finish is critical, you know how seemingly “uncontrollable” costs erode already thin margins.

Our free guide shows you how to address one of the most common problems plaguing companies like yours: Orange Peel.