At Saint Clair Systems, we build technology that controls temperature and viscosity - creating huge savings in time and material caused by “uncontrollable” variations. Learn how we can support your process.

DOWNLOAD THE GUIDE“Normal” temperature fluctuations significantly impact viscosity, which can lead to massive cost overrruns - and you’d never know it. The costs show up as:

Use the calculator to determine how much money you’re leaving on the table.

Normal daily temperature fluctuations could be costing you as much as

Failure to control temperature at the point of dispense leads to viscosity variations, which create...

Have you noticed film peeling off the surface of material you thought it was bonded to?

Learn more

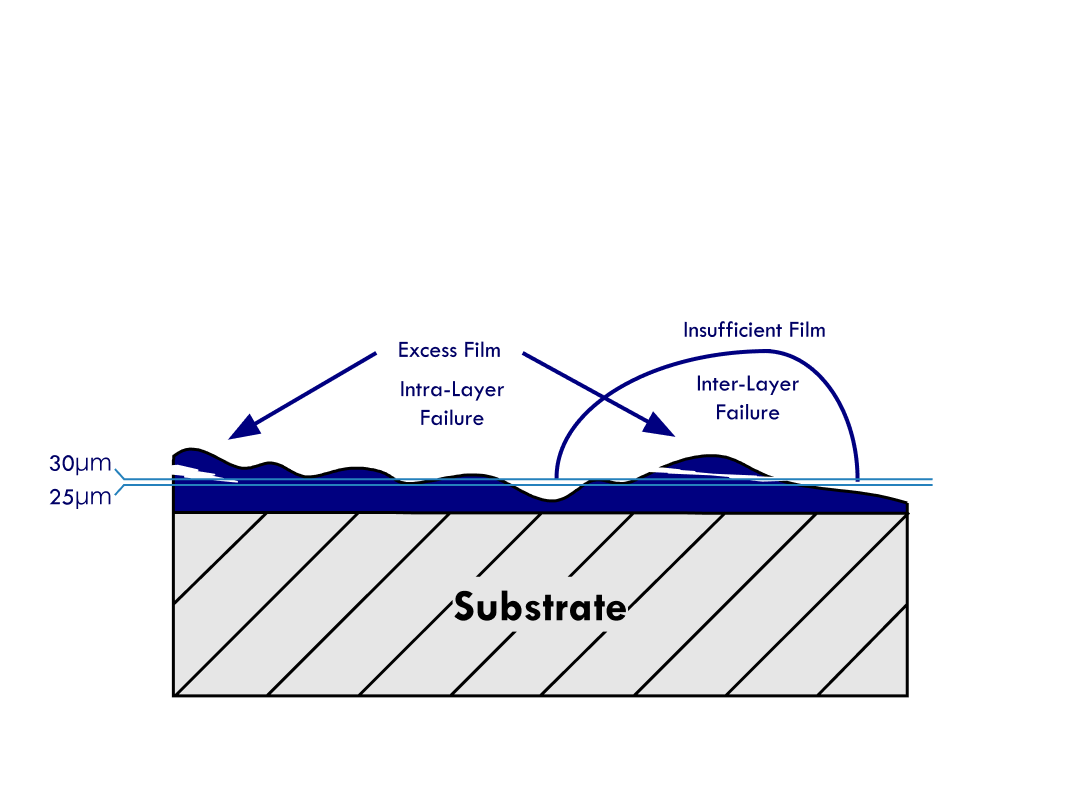

Improper viscosity leads to uneven film, which means excess film in some places and insufficient in other places.

Learn more

Controlling temperature at the point of dispense allows for smooth application of the film, reduced defects, and reduced costs.

Learn moreFREE VIDEO

Our free video shares the surprising impact that temperature and viscosity have on common defects and how to deal with them.

Download our free guide as a quick and easy reference..

DOWNLOAD THE GUIDE