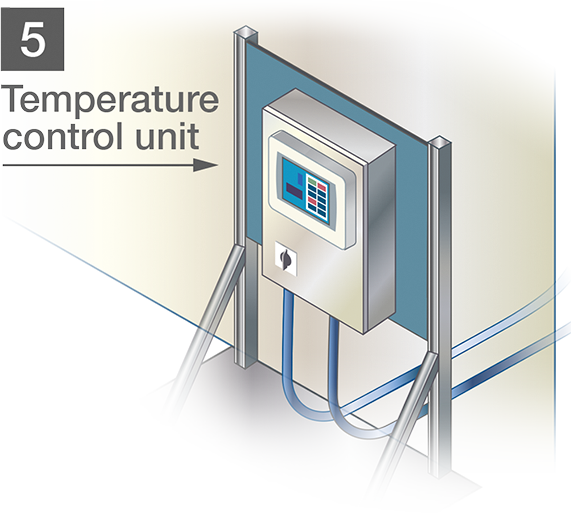

Our temperature and viscosity control solutions make your finishing process more consistent and less wasteful.

View Products or request a process evaluationVariations in temperature cause can disrupt production, limit throughput, and restrict capacity - leading to hundreds of thousands or millions of dollars in extra expense and lost time.

In this video case study, learn how Saint Clair Systems temperature control technology can get your production back on track.

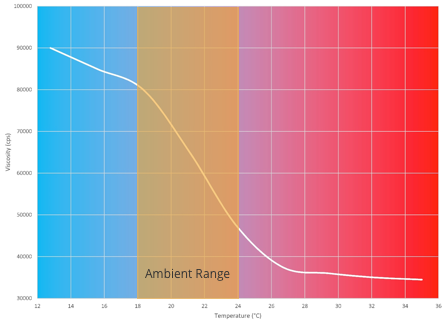

As temperature increases, viscosity decreases and vice versa. While automotive and industrial pain has a magnitudinal shift from 50-350 cps, the for sealers & adhesives is much higher: running from 30,000 to 1 million cps!

Whats more, this change happens right in the middle of the ambient range - between 18 & 26C. If you're having trouble with your sealer application, temperature could very likely be the culprit.

.png)

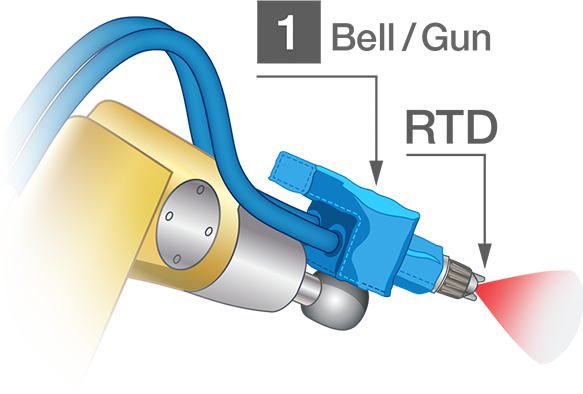

The RTD senses temperature in the material path as close to the Point of Dispense as practical, ensuring that it’s always accurate.

Video: Making Sealer and Adhesive Behave #1

Play VideoVideo: Making Sealer and Adhesive Behave #2

Play VideoInfographic: Effects of Temperature on Sealer Applications

Download NowArticle: Robotics World (May/June 2000)

Download NowArticle: ASI Adhesives & Sealants Industry (March 2017)

Download Now