Saint Clair Systems has developed methods to measure and analyze, in real time, the temperature of coating materials across the width and length of the strip, ensuring consistent film builds from edge to edge and head to tail. Our coil coating systems eliminate inconsistencies in manual viscosity measurements and adjustments by controlling viscosity with temperature.

With the ability to control coating temperature, you can ensure a stable and repeatable coating viscosity. This allows other process variables, such as roll speeds and nip pressure, to become definable and repeatable, reducing set-up time and scrap.

The Saint Clair Systems patented PCM creates the performance of a three-roll nip-feed coating configuration on a standard two-roll coater, without all the complexities.

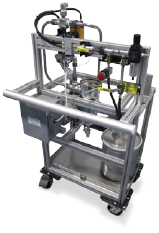

Coil coating systems require multiple color and formulation changes daily. Our patented Heat Exchanger Cleaning Station, enhances operating efficiency by improving heat exchanger performance and longevity.

Even when saturated with paint, used solvent is still functional. The BECCA systems effectively removes the solvent from the paint solids for recycling. Saint Clair Systems is the sole distributor of the BECCA system into the worldwide coil coating industry. This system:

Founded in 1990, Saint Clair Systems is dedicated to the science of temperature control and delivering fluid process control solutions that will help our customers enhance productivity and improve their bottom line.

Our customized solutions are designed to replicate the best time of the year, best time of day, and best conditions to run production, regardless of variations in ambient temperature or process generated heat.

At the end of the day, our customers can realize many benefits, including: