The AT-5900 Temperature Control Unit provides an effective method to monitor and maintain material temperature by heating or cooling fluids during operations.

The TCU heats, cools and circulates the closed-loop conditioning water through heat exchangers and ancillary components to ensure proper temperature of the coating material throughout production.

A temperature sensor located in the coating fluid stream sends the material temperature to the PID controller, which automatically determines whether heating, cooling, or no action is required.

The AT-5900 temperature control unit can be customized to meet specific production requirements for size, heat exchanger mounting, and pump volume

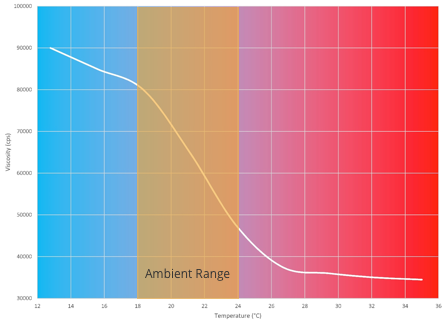

As temperature increases, viscosity decreases and vice versa. While automotive and industrial pain has a magnitudinal shift from 50-350 cps, the for sealers & adhesives is much higher: running from 30,000 to 1 million cps!

What’s more, this change happens right in the middle of the ambient range - between 18 & 26C. If you’re having trouble with your sealer application, temperature could very likely be the culprit.

The AT-5900 is a core part of a system designed to keep material temperature managed and costs under control. These components comprise a functional material control solution. Contact us for a free process evaluation and we can help you determine what components will help you accomplish your goals.

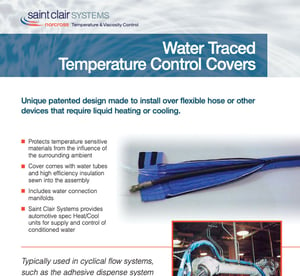

Covers flexible hoses or other devices in order to protect the temperature of temperature-sensitive materials flowing through your dispense system.

This patented hose turns the material supply hose into a flexible heat exchanger. It senses temperature in the material stream and maintains temperature - even if the flow stops.

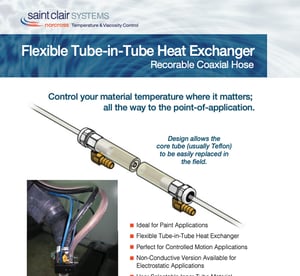

This patented heat exchanger is perfect for controlled motion applications, such as painting & sealing applications. Compatible with both gun and bell dispensing systems, it’s easily replaced in the field, minimizing operational disruption.

Turn your header into a heat exchanger with this patented peripheral. It can be installed quickly & easily - even during production - and helps to moderate temperature from the source to the point of dispense.